Tentang Indah Kiat Tangerang

PT. Indah Kiat Pulp & Paper Tangerang didirikan pada tahun 1976. Perusahaan telah memproduksi kertas bebas kayu selama lebih dari 30 tahun. Di tahun 90-an, sebagai Pabrik Kertas Pertama di Indonesia yang bersertifikat ISO 14001, Indah Kiat juga mulai memproduksi kertas khusus. Puncaknya mencapai puncaknya pada tahun 2006, ketika Indah Kiat mencapai produksi kertas warna 100%. Sejak saat itu, PT. Indah Kiat Pulp and Paper Tangerang Mill telah berkembang menjadi salah satu produsen kertas warna terbesar dan converter kertas khusus.

Visi

Menjadi perusahaan Pulp & Paper nomor satu abad ke-21 dengan standar internasional tertinggi di dunia, dan dengan komitmen kuat untuk memberikan nilai superior kepada pelanggan, pemegang saham, karyawan, dan masyarakat.

Misi

- Meningkatkan pangsa pasar global

- Menggunakan teknologi mutakhir dalam mengembangkan produk baru dan pencapaian efisiensi pabrik

- Meningkatkan kualitas sumber daya manusia melalui pelatihan dan pembinaan budaya perusahaan

- Mewujudkan komitmen keberlanjutan di semua operasi

Sejarah

PT. Indah Kiat Pulp and Paper (IKPP) is an FI (Foreign Investment) company which established by joint venture of an Indonesian company (PT. Berkat Indah Agung) and two Taiwan companies (Chung Hwa Pulp International Corporation dan Yuen Foung Yue Global Investment Corporation). In the practical world, the Taiwan companies act as the technology supplier for the paper making process, while the Indonesian company acts as the access supplier.

Eka Tjipta Widjaya established IKPP on December 7th 1976 in Tangerang. At the beginning, in 1977, this company only had two paper machines that had production capacity of 100 tons/day for each machine. On April 1979, IKPP began to produce commercial products. By June 1982, IKPP added one more paper machine to increase the production capacity to 150 tons/day. On March 1984, this company succeeded in producing commercial products; and later on April 1988 there has been several modification and reparation on its paper machines. These efforts increased the paper production until 250 tons/day.

On January 1986, Sinar Mas Group bought 67% of IKPP's shares, while Chung Hwa Pulp International Corporation and Yuen Foung Yue Global Investment Corporation held 23% and 10% each. On June 1990, IKPP began to go public by entering the share market in Jakarta Stock Exchange (JSE) and Surabaya with US$ 326 million that represented 13% of the total shares.

On December 1992, IKPP officially acquits PT. Sinar Dunia Makmur, a paper company that had been become a PT. Sinar Mas Group member that located at Kragilan Village, Serang - Banten. Later, on October 1996, PTIKPP add a dyer to one of its machine to increase the production capacity to 120.000 tons/year. On 2006, the ownership shares of IKPP was owned by 4 companies; PT. Puri Nusa Eka Persada (57.25%), Chung Hwa Pulp Int (BUI), Co (16.11%), Yuen Fuon Yue Invest Co (7.62%) dan public (19.02%).

Nowadays, IKPP has three factories that located in different locations; integrated pulp and paper factory that located in Perawang - Riau, industrial paper factories that located in Serang - Banten, and IKPP Tangerang that has the smallest capacity amongst others.

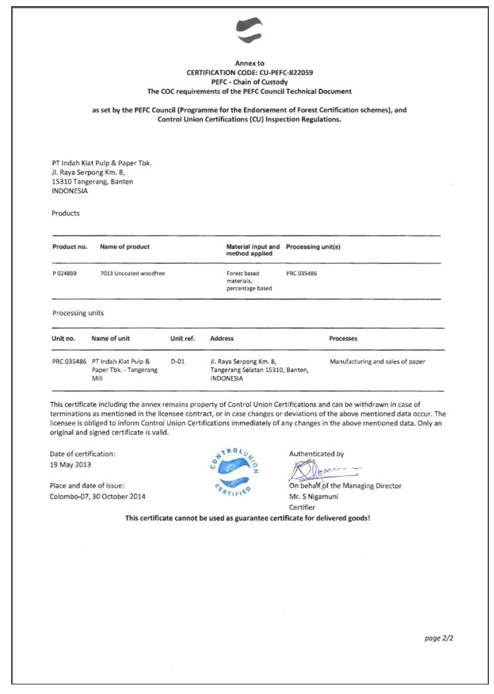

IKPP Tangerang has three Foudrinier paper machines with trimming width of 2.75 m and total production capacity of 135.000 tons/year. This factory produced color paper and board, photocopy paper, stationery products, etc. These all type of paper is fabricated from LBKP (short fiber pulp) and NBKP (long fiber pulp). IKPP Tangerang implements Chain of Custody of Forest Based Products (PEFC) that make the raw pulp material can be tracked until the forest it was taken from.

The Mills

There are several structural steps of paper making process. It starts from the preparation process of raw material in stock preparation. In this section, the raw material required for production are carefully managed and prepared. IKPP Tangerang has 3 paper machines to produce color paper with the capacity of 100,000 ton paper / year. By using high technology cutting machines, IKPP Tangerang cut the jumbo roll into the sheet and roll. By using the new machines and latest high technology, IKPP Tangerang convert its products into high value added product.

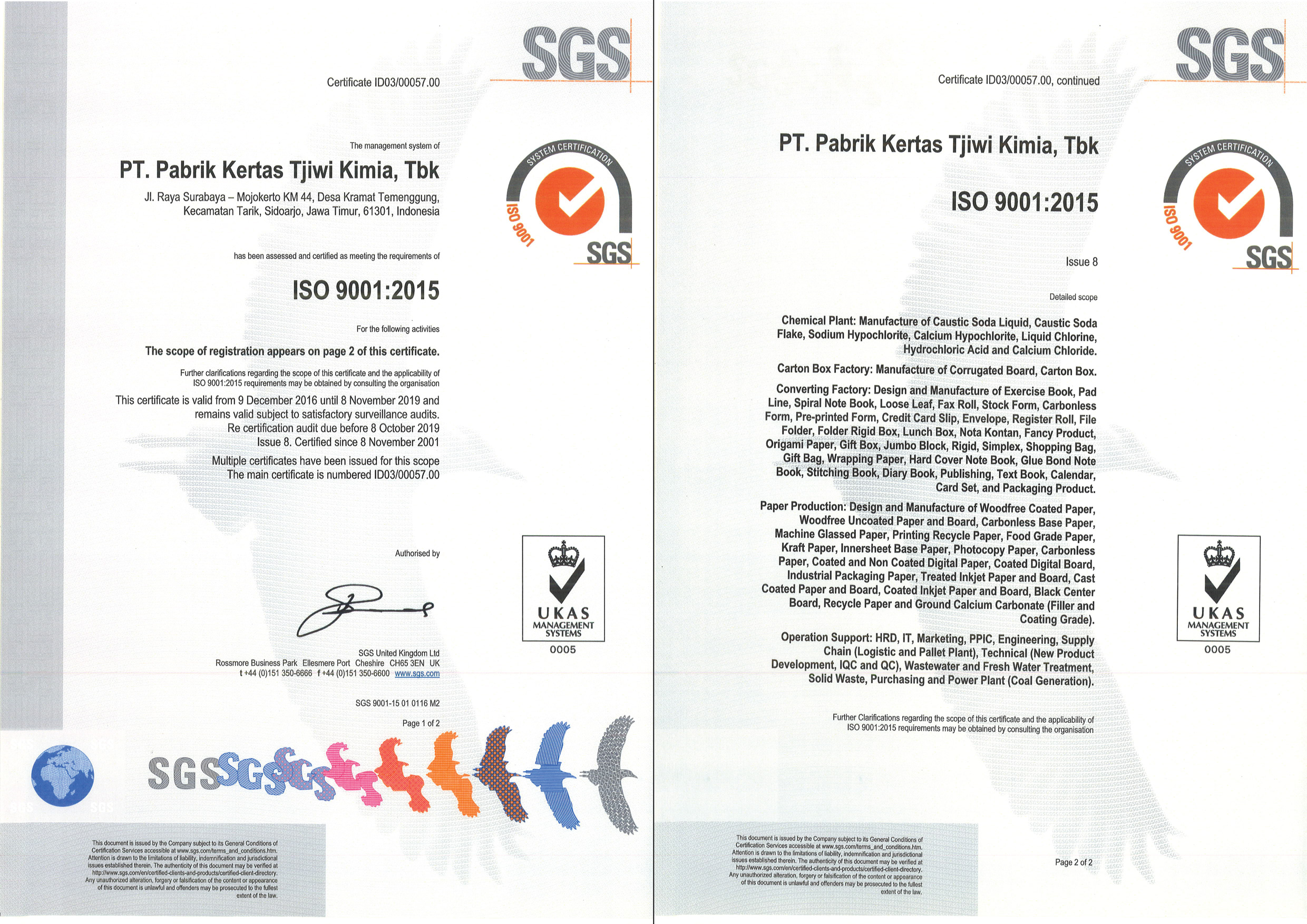

In any production process, company concern about quality. As a form of appreciation, IKPP Tangerang successfully obtain ISO certification 9001 (Quality Management System). Besides quality, company care about the health and safety of its employees. IKPP Tangerang successfully obtain ISO certification ISO 45001, SMK3 and awarded P2- HIV AIDS Category Platinum and Zero Accident Award form Ministry of Manpower of the Republic of Indonesia, and the best P2K3 from Banten province.

Cutter Rewinder

Stock Preparation

Converting Process

ISO

ISO 26000 : 2010

Certified Since:

28 September 2017

Valid Until:

12 September 2020

ISO 9001 : 2015

Certified Since:

9 December 2019

Valid Until:

8 November 2022

ISO 45001 : 2018

Certified Since:

13 December 2019

Valid Until:

30 October 2022

ISO 9001 : 2015

Certified Since:

28 September 2017

Valid Until:

12 September 2020